ColorLite sph9i

Industrial Online Colour Monitoring

ColorLite sph9i

Fully automated spectrophotometer for 100% production control

Advantages

- Reduces waste, saves time and costs

- Very high repeatability thanks to high resolution spectral measurement

- Long-lasting and balanced high-power LED light source

- Different probe heads for various applications – reflection and transmission

- Easy communication to your process control system – ProfiNet, ProfiBus, Ethernet

Our inline colour measurement systems are custom made for your production line.

We offer the best full-service package with expert advice, installation, remote service, employee training, maintenance package and first-class aftersales support.

Colour is an important quality attribute of almost all products in production. The ColorLite sph9i is complemented by various probe heads variants and a wide range of accessories. Therefore the ColorLite sph9i system ensures colour measurement in different areas such as plastics, paper, textile and food industries. Permanent quality control minimizes waste in the production plant, effect increasing productivity by reducing time and costs.

Applications

- Reflection light colour measurement of granules, recycled pellets, regrind, extrudates and injection molding components

- Reflection and transmitted light measurement of films, PET packaging, textile fabrics and paper webs

- Measurement of liquids e.g. with a dipstick probe

- Other applications on request – we are happy to support you!

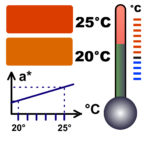

Measurement principle

Spectral colour measurement is the most accurate measurement method to achieve consistent and best-reproducible measurement results. The samples are illuminated with homogeneous, white light of high power LEDs. The surface of the product is scanned spectrally in 3.5 nm steps. The wavelength coordinates of 400 to 700 nm are shown in the desired colour scale. The ColorLite sph9i takes into account the appropriate type of light and the observer angle of the selected probe head variant.

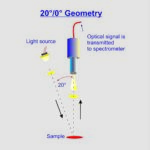

| Measurement Geometry | 45°/0°; d/8°; 20°/0°; d/0° - Measurement area of 2 mm to 80 mm |

| Illuminants | D65, D55, A, C, F11 |

| Standard Observer | 2° and 10° |

| Colour Scales | XYZ, Yxy, ΔE CIE L*a*b*, L*u*v* |

| Quality Control Tolerance Limits and Colour Differences | ΔE CIELab; ΔL, Δa, Δb; ΔL, Δu, Δv; ΔL, ΔC, Δh, ΔECMC (1:1 und 1:2), CIE ΔE94, ΔE2000 |

| Spectral Range/ Wavelength | 400 nm to 700 nm |

| Spectral Resolution | Holografic grating-Spectrometer FWHM @500 nm < 10 nm Scanning in 3,5 nm intervals Resolution: 115 x 16-Bit per scan |

| Memory | FRAM, Memory of 1000 standard colours und 200 standards |

| Repeatability | < 0,05 ΔE CIELab (measurement on a white surface) |

| Light Source | White and blue LED´s Life span > 20 years |

| Power Supply | 24 VDC |

| Ambient temperature | 15 °C to 55 °C |

| Relative humidity | max. 85% not-condensing |

| PC-Interfaces | Serially USB, RS232 (isolated) Optional: CAN, Ethernet, PROFIBUS, PROFINET (all isolated) |

| Digital input-/ and output | 4/4-Kanal digital I/O for status of process control system 4 isolated input 0-30V 4 isolated output 0-30V, Power current load 0,7A / channel |

d/0° probe head – measuring inhomogeneous samples

The d/0° measuring heads ( and -adapters) MA38 and MA80 illuminate the sample with a diffuse LED light source on an area of 38 mm or an 80 mm respectively. These versions are used to measure inhomogeneous samples such as granules, food, wood paints or…20°/0° probe head – for measuring with distance

Probe head for basic system sph9i The 20°/0° measurement geometry makes it possible to reach an independent height for measuring colours with an gap up to 80mm. The probe is being directly illuminated in an 20° angle and the than diffused reflected lig…Probe head special version dipstick for measurement of liquids, powders etc.

Probe head for the sph9i spectrophotometer Measuring geometry: d/0° Protection class IP67 Integrated LED light source With sapphire glass (edged in a stainless steel mount and replaceable) Material: stainless stell, hermetically sealed Calibration Stan…Inline colour measurement has arrived in modern production

The increasing demand for inline measuring technology is caused by the growth of automation and networking in the production. ColorLite offers customer-specific solutions with intelligent networking to their process control system. The sph9i online spectrophotometer is available with various probe heads, modern industrial interfaces and extensive accessories. Due to the high degree of precision, it is possible to react quickly to deviations during ongoing production process. It is used in different industry areas such as the plastics, paper, textile and foods.

A real-life example success story

Online colour measurement on steel coil at Salzgitter AG

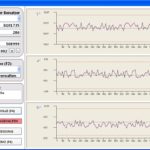

With the online spectrophotometer sph9i the colour values are continuously measured and controlle during the running coil coating process. The system is equipped with an infrared sensor for measuring the material temperature and subsequent thermo-chromatic compensation. Furthermore, the system has a fully automatic calibration unit. The operator terminal is supplemented by an industrial PC and a touch screen monitor.

Follow download link -> Farbmesstechnik bei der Salzgitter AG

__________________________________________________________________________________________________________________________________

Further application examples:

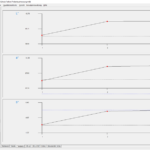

Colour and optical density measurement in the plastic sheet production

The ColorLite system is characterised by the highest quality and easy using. Measured values are visualised on the integrated display and can be stored for later reference with optional SQL database software. The system can measure inline up 5 density units (D5). The completion of a colour change is no longer a guessing game. The device automatically controls the dosing unit where the colour starts to deviate from the standard, thus avoiding an the production of out of range goods. There is no waste and thus no expenses.

Granule measurement through glass

The measuring system consists of a touch screen PC built into a control cabinet, as well as the

proven sph9i spectrophotometer, the measuring head MA38-VA with a d/0° geometry or our MA80

which measures over a diameter of 80mm. The MA38-VA can be provided with an automatic

calibration unit.

Control units can by interfaced directly to automatically sort out off range during the production –

No time delay – No Waste